USA Plastic Parts Manufacturer

Designer, Builder & Manufacturer of Custom Plastic Components

Retlaw Industries is headquartered in Hartland, WI, lending an advantage in supplying quality thermoplastic OEM components to the U.S. East Coast, the West Coast, and all points in between. As a leading plastic injection molding company, we specialize in creating custom plastic parts suited to your exact specifications. With decades of experience and state-of-the-art facilities centrally located in Southeast Wisconsin, we take your product from initial concept to full-scale production.

Our Custom Capabilities

- Part Design - Our engineers design plastic parts to meet your functional needs

- Prototyping - We test out concepts before full production

- Material Selection - We use the ideal plastic for your specific application

- Precision Mold Building - We craft precise molds to yield complex and accurate plastic parts

- Short & Long Production Runs - We do everything from small batches to high-volume runs

- Secondary Operations - Including assembly, decorating, packing and more

- Just-In-Time Delivery - For lean supply chain integration

Trust us for end-to-end custom plastic injection molding solutions tailored to your needs.

Retlaw Industries Serves Clients in All 50 United States

Plastic Injection Molding in

We Handle the Entire Plastic Injection Molding Process

| Design/Engineering |

Our engineers design plastic parts tailored to your specifications, conducting mold flow analyses to optimize the mold design. |

| Tooling/Machining |

We expertly craft injection molds, applying precision machining processes to create complex cavities for accurate plastic parts. |

| Injection Molding |

We input plastic granules into molding machines to produce plastic parts with consistency and efficiency of scale. |

| Assembly |

From simple snaps to complex connections, we assemble plastic parts and components to build sub-assemblies or finished products. |

| Quality Control |

With rigorous inspection and testing, we ensure all plastic parts meet approved samples and your exact standards for fit, form and function. |

Plastic Product Capabilities

Retlaw Industries is a premier supplier of molded plastic components across the United States. We specialize in precision thermoplastic injection molding, and our expertise includes:

- Experienced Engineering Design Team - We expertly design plastic parts for optimal manufacturability

- Stringent Quality Assurance - With rigorous inspection testing, we guarantee products are built to exact standards

- State-of-the-Art Facilities - Our advanced manufacturing technologies produce consistent, high-quality plastic components

- Diverse Industries Served - Our parts are trusted by leading brands across industries

- Customer-Focused Production - Our flexible capabilities allow us to scale production as needed

Retlaw Industries delivers tailored, precision-molded plastic parts you can trust across the U.S. Contact us to learn more!

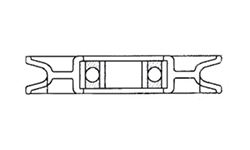

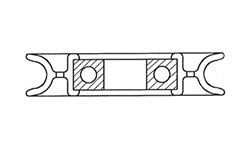

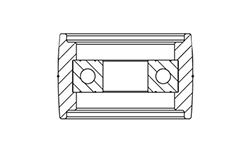

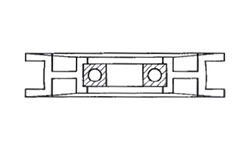

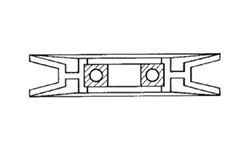

Idler Pulleys

Retlaw Industries produces plastic idler pulleys for use in belt and pulley systems across a range of industries. Our extensive inventory includes pulleys with different channel depths and belt compatibilities to suit diverse applications. We stand behind the durability and performance of our glass-reinforced nylon pulleys, which run cooler, prevent rivet fatigue, extend belt life and resist corrosion compared to metal alternatives. Whether you're seeking v-belt or round belt idlers or requiring custom-engineered pulleys, Retlaw is ready to meet your application's unique demands.

Retlaw Industries delivers consistent, top-quality idler pulleys ideal for guided belt movement in machinery. Available to ship nationwide, our pulleys enhance performance through smooth operation and vibration dampening across countless cycles.

|

|

|

|

|

|

|

Adapters

Retlaw Industries offers pulley and sprocket adapters to accommodate different styles and bore sizes. We produce adapters and other plastic parts for industries like lawn care, automation, construction, food production and more. From our Wisconsin headquarters, we develop ideal parts for your mechanical systems with careful craftsmanship and customer-focused service.

Sprockets

Retlaw Industries manufactures high-quality plastic roller chain sprockets used to transmit rotational motion between shafts. Our sprockets precisely mesh with roller chains in mechanisms like bikes, motorcycles, cars, tracked vehicles and heavy machinery.

Our team produces reliable sprockets in diverse sizes and tooth counts, and our extensive in-stock inventory meets common application needs while our custom engineering capabilities handle unique requirements. Paired with our idler adapters for proper shaft fit, our American-made sprockets drive power transmission under demanding conditions across countless cycles.

Rebar Chairs

We manufacture high-quality plastic rebar chairs used in concrete reinforcement across construction industries. Our rebar chairs properly space steel rebars in poured foundations and structures for strength. Unlike metal chairs, Retlaw's rustproof chairs maintain building integrity over time. Our chairs optimize spacing to withstand stresses with snap-lock installation and the ability to accommodate a range of rebar sizes.

Retlaw produces lightweight single-direction, dual-direction and rebar clip chairs for easy handling on work sites. Trusted by companies nationwide looking to reinforce poured concrete slab foundations, our rebar chairs deliver proven performance across infrastructure projects.

See Plastic Materials Retlaw Industries Works With

- Polystyrene: Thermoplastic injection molding frequently uses polystyrene, a solid, clear and non-toxic plastic polymer, because of its versatility. Polystyrene can be molded into many industrial and consumer products like food packaging, electronics, automobile parts and toys. As a foam or rigid plastic, polystyrene works well for applications like industrial automation components and plastic utensils due to its solidity, clarity and odorless quality.

- Polypropylene: Polypropylene's versatility allows it to be customized by blending it with materials like rubber to form robust copolymers tailored to specific mechanical needs. Polypropylene is an ideal choice for food containers because it is naturally BPA-free. Unlike Bisphenol A, a synthetic compound which can leach into foods and pose health risks, polypropylene's chemical structure prevents unwanted migration issues and withstands high heat, keeping foods safer for human consumption.

- Polyoxymethylene: Polyoxymethylene is a high-strength plastic blend valued in injection molding for its exceptional impact/flexural strength, hardness, durability, dimensional stability and chemical/heat resistance; unlike other thermoplastics, polyoxymethylene melts instead of burning when heated, making it useful for low-friction applications, however its vulnerability to hydrolysis and oxidation requires innovative manufacturing methods.

- Polyetherimide: With high impact strength, dimensional stability, heat and chemical resistance, polyetherimide is an engineering thermoplastic used in challenging automotive, chemical processing and lighting applications demanding resilient properties under extreme conditions. Polyetherimide’s inherent safety features like flame retardancy and electrical insulation deliver reliable performance outweighing weaknesses like cost for products subject to demanding environments.

- Polycarbonate: Polycarbonate is a transparent, amorphous copolymer engineering thermoplastic which liquefies when hot, allowing injection molding for lightweight, shatter-resistant products with high-impact strength, heat resistance and optical clarity ideal for applications ranging from eyeglasses to durable food containers.

- HDPE: Retlaw Industries expertly manufactures durable, affordable high-density polyethylene molded components across a wide variety of industrial applications from roller chain sprockets to idler pulleys, leveraging extensive plastic injection molding design, tooling, production and assembly capabilities to deliver trusted OEM thermoplastic parts.

- Nylon: Nylon is a versatile, durable thermoplastic alternative to silk, rubber or latex. Nylon is chosen for high-temperature injection molding due to its low friction, tensile strength, impact resistance, chemical compatibility and recyclability via melting instead of burning to create components like fiberglass-filled molded engine parts and other high-friction machine elements.

- Acrylic: Acrylic, also known as Poly(methyl methacrylate), is a clear thermoplastic homopolymer widely utilized as a durable alternative to glass, offering transparency, weather and chemical resistance, surface hardness, dimensional stability and a non-toxic composition; its versatile properties make it a common choice for various applications from windows and picture frames to artificial nails and paint. Acrylic is economically moldable by experts like Retlaw Industries.

Providing Plastic Injection Molding for Over 10 Industries

Retlaw provides high-accuracy plastic OEM services for numerous industries across the United States, including:

- Fitness and Health

- Lawn and Garden Care

- Warehousing

- Construction

- Transportation

- Electronics

- Automation

- Food Production

- Appliances

- Agriculture

Serving Companies Midwest & Nationwide

Contact Retlaw Industries for a quote on your next plastic part project. Our centralized geographic location allows us to easily supply our high-quality injection molded plastics to not just Milwaukee and Wisconsin, but industrial hubs like Chicago, and recent manufacturing revival cities like Toledo, Ohio and the Detroit-Dearborn-Livonia areas in Michigan, and all points extending from there.