What are Flat Idler Pulleys Used For?

Flat idler pulleys are shallow, flat-channeled pulley wheels used with standard drive belts, cog belts, poly-V belts, and the back side of conventional V-belts. Retlaw’s flat idler pulleys feature one-piece construction for more durability than the competition. Using concentric bearings with +/-0.007 total indicated runout, our plastic flat idler pulleys will run smoothly throughout their lifespan, ensuring the best performance for your conveyor belts.

Composite Flat Idler Pulleys for Sale at Retlaw

Retlaw Industries has ready-made flat idler pulleys of all sizes to meet the needs of your product’s belt-driven subsystems. Our glass-reinforced thermoplastic pulleys are precision molded by our expert composite plastic manufacturers, run cooler than metal idlers and are resistant to most oils and solvents.

Flat idler pulleys from Retlaw are commonly used with belt pulley systems as tensioners and idlers, but can also be converted into driving systems with our drive adapters.

Flat Idlers for Every Industry

Plastic idler pulleys from the professionals at Retlaw are made for a wide variety of businesses throughout the United States. Since 1977, we’ve produced high-quality glass-reinforced thermoplastic idler pulleys in multiple sizes, supplying companies with sturdy flat idler pulleys for a wide variety of applications including:

- Lawn mowers

- Fitness equipment

- Power transmission systems

- Automation systems

- Conveyor belts

- And much more

From initial design to final assembly, the professionals at Retlaw Industries will manufacture your plastic flat idler pulley with the highest quality products at the lowest possible price.

Additional Features of Flat Idlers from Retlaw Industries:

- Corrosion resistant throughout

- Low friction coefficient

- No rivet fatigue

- Bearings sealed A.B.E.C. 1 with sintered metal hubs.

- Standard bearing numbers 6203-2RS

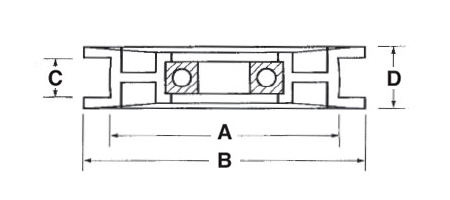

Retlaw Sizing Info

Retlaw Industries manufacturers several types of products. If you are interested in an adapter or idler pulley size that is not currently on our size chart, please contact us.