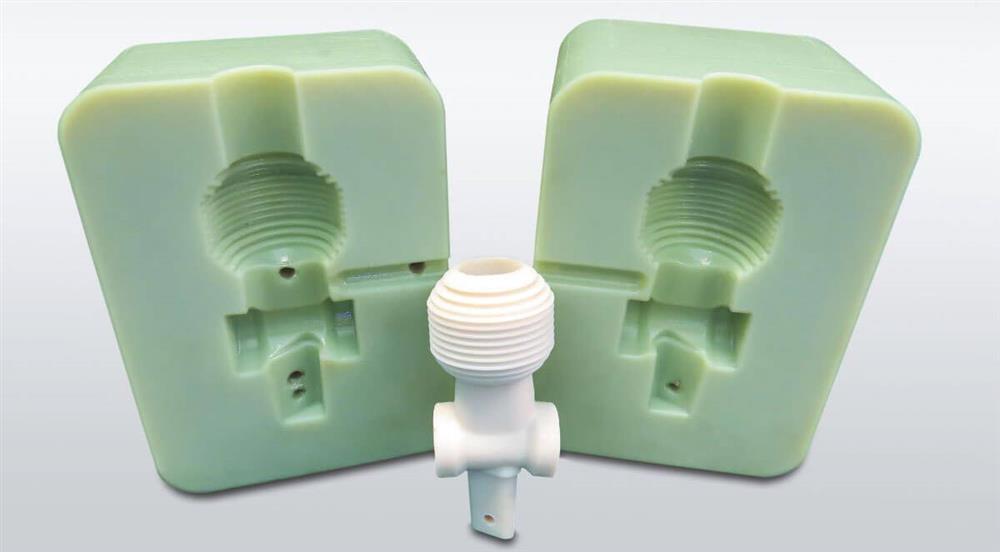

Prototype Injection Molding

Retlaw are experts in plastic injection molding, which we leveraged to create our plastic prototype service. Prototype injection molding is the process of creating a plastic prototype of your specific design before manufacturing to ensure accuracy and minimize risk. Rapid injection molding prototyping is the preferred method because it helps confirm part quality and can be market-tested prior to finalizing the design.

Benefits of Plastic Rapid Prototyping

Quick and reliable manufacturing: Plastic prototype manufacturing reduces the risk of product failure, which costs time and money. With our rapid injection molding prototyping, you can ensure your product is ready for launch because you can quickly and easily make adjustments to style and functionality.

Increased design process efficiency: Plastic rapid prototyping can help shorten the engineering and design process of creating a specific product. Having physical prototype plastic parts makes it incredibly easy to identify possible changes necessary to meet your exact specifications.

Reduced cost: Manufacturers who skip prototyping often have to readjust their final product molds, which is incredibly expensive and inefficient. Plastic prototype manufacturing allows you to perfect your product prior to creating the mold for production.

Types of Plastic Used in Prototype Injection Molding

There are 7 types of commercial plastics that are most commonly used in everyday items, which are available for any of your prototyping needs. Each kind of plastic has different properties that offer you a variety of benefits based on the product you need.

Polyethylene Terephthalate (PET or PETE): Keep your food and drink safe with PETE. This plastic prevents oxygen from getting in and spoiling any product inside and is inexpensive, lightweight, and highly recyclable. The most common products used with this type of plastic are drink bottles, food containers, and soap bottles.

Polyethylene Terephthalate (PET or PETE): Keep your food and drink safe with PETE. This plastic prevents oxygen from getting in and spoiling any product inside and is inexpensive, lightweight, and highly recyclable. The most common products used with this type of plastic are drink bottles, food containers, and soap bottles.- High-Density Polyethylene (HDPE): HDPE is one of the most popular materials used in thermoplastic manufacturing, accounting for about 34% of the world's plastic materials. It is incredibly resistant to environmental exposure and is very eco-friendly. Products commonly made from HDPE are toys, reusable bottles, chemical containers, recycling bins, and outdoor signage.

- Polyvinyl Chloride (PVC): PVC comes in either a rigid form or a flexible form. The rigid form is commonly seen in piping, while the flexible form is often seen in products like wire insulation. This type of plastic is highly chemical-resistant and is able to withstand acids, alcohols, and more. PVC is often used in products such as pipes, medical devices, wire insulation, packaging, and flooring.

- Low-Density Polyethylene (LDPE): LDPE is known for its lightweight, flexible, and soft plastic material, which is used to make thin and flexible products. Common products made from LDPE are plastic bags, wire insulation, and plastic film.

- Polypropylene (PP): This type of plastic is tough, rigid, and crystalline plastic that is lightweight, heat resistant, and flexible. Products commonly made from PP include straws, consumer product packaging, car parts, luggage, and textiles.

- Polystyrene (PS): PS is often used in the food packaging and electronic industries because of its non-toxic and odorless traits. It comes either as a solid plastic or a rigid foam material. Some common products made from PS are appliances, rubber tires, TVs, computers, and medical equipment.

- Other: We also offer polycarbonate, acrylic, and nylon for any of your plastic prototype manufacturing needs.

Your Trusted Prototype Injection Molding Company

Retlaw Industries specializes in injection molding for thermoplastic OEM parts. You can trust that we will provide quality prototype plastic parts because it is in our heritage. As an American Society for Quality member, we proudly adhere to strict quality control standards. Get your plastic prototype manufacturing project done right with Retlaw Industries.

Prototype Injection Molding Available Nationwide

Retlaw Industries proudly provides custom prototype injection molding services for all 50 states, including but not limited to: Wisconsin, New York, Pennsylvania, Washington, Indiana, Colorado, Michigan, Massachusetts, and Ohio!