Retlaw Industries is a leading American manufacturer of high-performance, injection-molded plastic roller chain sprockets. Engineered to be a quiet, corrosion-proof and lightweight alternative to metal, our sprockets are trusted in demanding industrial applications across the country.

We specialize in producing both standard ANSI sizes and fully custom roller chain sprockets, providing a reliable and cost-effective solution for your power transmission needs.

Why Choose Plastic Sprockets for Your Roller Chain System?

Our thermoplastic sprockets deliver significant advantages over traditional metal sprockets, improving performance and reducing your total cost of ownership.

- Eliminate Corrosion & Reduce Maintenance: Unlike metal, our plastic sprockets will never rust. This makes them the ideal choice for washdown environments, food production, agricultural applications, and any machinery exposed to moisture or chemicals.

- Reduce Noise & Extend Chain Life: Plastic is naturally quieter and less abrasive on roller chains than metal, leading to smoother operation and longer chain service life.

- Lightweight with High Impact Strength: Reduce the overall weight and inertia of your system without sacrificing durability. Our engineered plastics are designed to withstand significant shock loads.

- Cost-Effective Precision: Through precision injection molding, we deliver high-quality, tight-tolerance sprockets at a more competitive price point than machined metal.

Custom Sprocket Manufacturing

While we offer a range of standard sizes, our specialty is creating custom sprockets tailored to your exact needs. As a premier custom sprocket manufacturer, we partner with you to develop the perfect component for your application.

Our capabilities include:

- Custom tooth counts and profiles

- Specific bore sizes and keyways

- Specialty materials for unique chemical or temperature requirements

- Molding in lightening holes or other features to reduce weight

Our Standard ANSI Sprocket Sizes

We manufacture sprockets that meet the stringent standards of the American National Standards Institute (ANSI).

- Chain #35: 19-Tooth Sprocket

- Chain #40: 17-Tooth Sprocket

- Chain #50: 15-Tooth Sprocket

- Chain #60: 13-Tooth Sprocket

- Chain #80: 12-Tooth Sprocket

All our standard sprockets come with a 17mm bore and are designed to be used with our versatile range of idler and drive adapters.

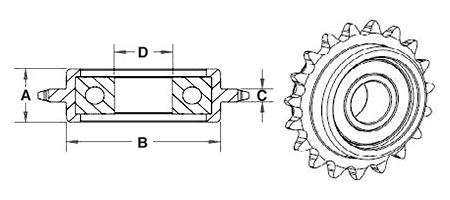

Retlaw Sizing Info

Retlaw Industries manufacturers several types of products. If you are interested in an adapter or idler pulley size that is not currently on our size chart, please contact us.

Industrial Applications for Plastic Sprockets

Our durable sprockets are designed for reliable performance in a wide range of industrial sprockets and machinery applications:

- Conveyor Systems (especially in Food Production & Warehousing)

- Agricultural & Lawn Care Machinery

- Packaging & Automation Equipment

- Fitness Equipment

- Construction Equipment

Your American Sprocket Manufacturer & Supplier

Retlaw Industries is your direct source for American-made sprockets. For over 40 years, companies have chosen us as their sprocket supplier because of our commitment to quality and our in-house capabilities. From our facility in Hartland, Wisconsin, we control the entire process from tooling to production, delivering world-class results for our OEM partners.