Nylon Injection Molding in Wisconsin

Retlaw Industries is a full-service manufacturer specializing in nylon injection molding and complete part production in Wisconsin. Bring early concepts, CAD files or ideation outlines, and our facility will handle tooling creation, parts molding, assembly and prototyping.

Our team combines deep injection molding experience with practical engineering support, giving projects clear direction from initial design through production and finishing. Vetted facilities, scale capacity and decades of proven manufacturing knowledge support high-precision molded nylon polyamide parts for demanding applications. Contact us today for a quote.

What is Nylon (Polyamide) Plastic?

Nylon, also called polyamide (PA), is a semi-crystalline thermoplastic commonly used in injection molding. Lightweight density, thermal stability, low friction performance and chemical resistance make nylon injection molding a standard choice for mechanical and industrial parts. The material takes dye well, liquefies when melted for recycling and maintains safety performance under high-friction and elevated-temperature applications.

Why Nylon (PA) Is a Standard for Injection Molding

Nylon PA is one of the most commonly molded plastics across industrial and mechanical markets. Low friction, chemical resistance, abrasion durability and thermal stability make nylon injection molding a standard for gears, fasteners, bearings and high-friction mechanical parts. Industries often shift to nylon polyamide as an accessible alternative to plastics, wood, rubber and metal.

High-Quality Characteristics for Nylon Injection Molding

Nylon is a synthetic thermoplastic polymer widely used for injection molding. Common benefits include:

- High melting temperature

- Low-friction surface behavior

- Strong tensile performance

- Resistance to chemicals and abrasion

- Reliable heat soak tolerance in friction-heavy mechanical parts

Retlaw Industries also molds glass-filled nylon polyamide into rigid, high-strength components requiring reduced flex behavior and elevated structural stability.

Get Custom Nylon Plastic Parts

Properties of Nylon Plastic (PA):

| Name | Nylon (PA), or Nylon Polyamide |

| Chemical Formula | (C12H22N2O2)n |

| Melting Point (°C) | ~220°C |

| Tensile Strength | ~11,000 psi |

| Impact Strength | ~0.6 fit-lb/in notched Izod |

| Hardness Level (Rockwell) | R115 |

| Flexural Modulus | ~16,000 psi |

Common Applications for Nylon Injection Molding:

Nylon injection molding supports the creation of parts and products, including:

Fabric

Fiber Ropes

Food Packaging

Toothbrushes

Cookware

Nylon is also widely molded into engine-supporting, rotating, friction-heavy and precision-fit mechanical housings.

Why Choose Retlaw for Nylon Injection Molding?

Retlaw Industries brings a full-service approach for nylon injection molding projects in Wisconsin and nationwide, blending internal tooling, engineering direction, scalable molding and assembly oversight. We have over 40 years of experience manufacturing custom components and assembling finished products with a long track record of success. Transparent quoting and in-house production oversight give projects continuity, clarity and execution consistency from concept through shipment.

Plastic Injection Molding Services

Design & Engineering: Early-stage support for nylon injection molding parts.

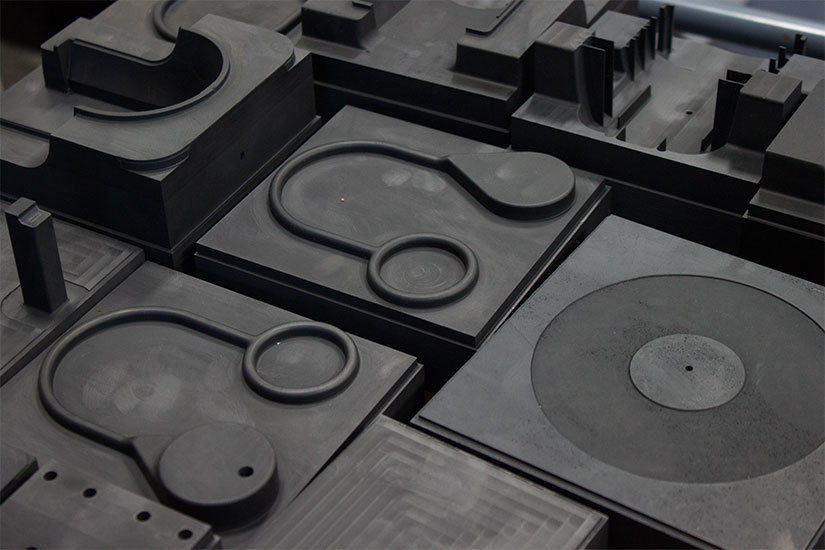

Tooling: Internal mold creation and adaptation for nylon polyamide.

Molding: High-quality nylon injection molding production.

Assembly: Precision-fit nylon polyamide component assembly.

Prototyping: Rapid nylon injection molding iterations.

Challenges with Nylon Injection Molding

Nylon injection molding material behaviors include:

- Gassing: Excess gas can impact surface appearance and part stability. Temperature tuning and controlled venting reduce gas-related molding effects.

- Moisture: Nylon PA takes in moisture when left in loaders and lines. Barrel heat soak and material line clearing support stable melt flow during nylon injection molding cycles.

- Shrinkage: Nylon shrinkage can occur during molding. Heat profiling, mold temperature control and cooling cadence reduce shrink-related effects.

Industries Supported With Nylon Injection Molding Parts

- Automation

- Fitness

- Lawn & Garden

- Electronics

- Construction

- Appliances

- Agriculture

- Food Production

- Warehouses

- Transportation

Nylon Injection Molding Services Available Nationwide

Retlaw Industries ships molded nylon parts to Wisconsin, Colorado, Illinois, Indiana, Michigan, Minnesota, New York, Ohio, Pennsylvania, Washington and nationwide!