Pulley and Sprocket Adapters for All Uses

An endless combination of pulley and sprocket styles, sizes, and uses means a variety of adapters will be needed to accommodate them. Adapters are inserted into the pulley’s bore, effectively customizing it to get the correct fit around the shaft. Retlaw Industries stocks an inventory of idler and drive pulley adapters so you can get the right pulley/adapter combination for your OEM needs.

Our adapters have precision, pre-lubricated ABEC-1 ball bearings to meet high speed demands and have durable sintered metal hubs. Stainless steel bearings with Viton seals are available upon request for special applications.

Available Adapter Styles

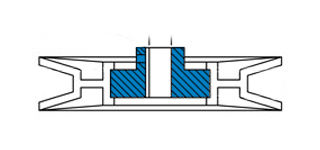

- Standard Bore Adapters – an unspecialized adapter with no standoff from edge of bore.

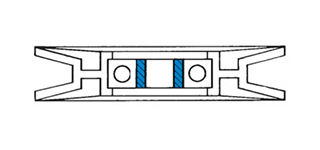

- Drive Adapters – used to convert idler pulleys into drive pulleys. A key way connects the shaft to the adapter which transmits rotational kinetic energy to the pulley. Our drive pulleys have a stand off extending from one side of the bore.

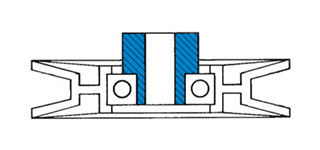

- Shoulder Adapters – idler bore adapters with a standoff extending from one side of the center bore.

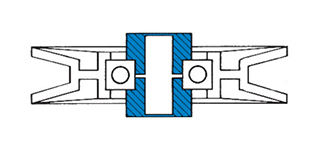

- Clevis Adapters – essentially a shoulder adapter, but with stand offs extending from both sides of center bore.

All of our idler and drive adapters are available in a range of bore diameters, widths and standoff sizes. If you can’t find the correct adapter size or style in our inventory, our designers will work with you to produce the adapter for your custom application.

Custom-Designed Thermoplastic Parts for Your Industry

Retlaw Industries designs custom plastic parts for industries just like yours. Through our unique plastic injection molding process high-quality assembly equipment, we can custom-make the parts your company needs for your particular application. We produce custom plastic parts for all types of industries, including:

- Lawn and garden care

- Fitness

- Automation

- Electronics

- Construction

- Appliances

- Agriculture

- Food Production

- Warehouses

- Transportation

- And much more

Plastic Adapters Made in the USA

All of Retlaw Industries’ plastic injection-molded products are manufactured right here at our Wisconsin facility, meaning you can be assured your molded part is going to be handled by a group of professionals who care deeply about their craft. The people at Retlaw have had years of experience in the plastic injection molding industry, which only solidifies our dedication to quality in everything we do. You’re sure to end up with the best possible plastic adapter for your particular application.

No pulley is complete without the proper adapter. Contact the engineers at Retlaw to get advice on selecting the proper pulley adapter application and place an order today.