Nylon (PA) Plastic Injection Molding

Retlaw Industries is a full-service manufacturer for plastic injection molding part design, custom tooling, part production, assembly and more! Whether you have a part design in mind, a fully developed CAD drawing, or are looking to start fresh, our shop has the equipment and resources to bring it to life as a completed product. Our team has the expertise and resources to reliably produce high-quality custom nylon (polyamide) parts regardless of size or complexity. With over 40 years of industry experience and a 6-acre facility full of the latest equipment and software, Retlaw Industries is the clear choice for businesses that demand nothing but the best. Contact us to discuss the specifics of your nylon (polyamide) injection molding needs!

What is Nylon (Polyamide) Plastic?

Nylon, also known as Polyamide, is a semi-crystalline thermoplastic with low density and high thermal stability. Nylon is easy to process, modify, and recycle and can be compounded or blended with other materials to increase performance and improve property characteristics. Nylon is derived from crude oil and can be dyed into various shades and can have either a glossy or matte appearance.

Why is Nylon (PA) So Commonly Used?

Nylon (PA) is one of the most widely used plastics in the world. It is an ideal plastic for a wide variety of applications due to its high melting point, low friction, and resistance to chemicals and abrasion. Used across industries, nylon plastic excels in industrial, mechanical and construction applications and often serves as an alternative to other plastics, wood, rubber, and metal materials.

Nylon (PA) Plastic Material Characteristics

Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications. It’s a versatile, durable, and flexible material often used as a more affordable alternative to other materials like silk, rubber, and latex. Material benefits of nylon polyamide include:

- High melting temperature

- Low friction

- High tensile strength

- Resistance to chemicals and abrasions

The chemical composition of Nylon gives it a high melting point, making it an excellent alternative to metal components in high-temperature environments, like car engines and other types of high-friction machinery. Like other thermoplastic materials, nylon plastic turns to liquid at its melting point rather than burning, meaning it can be melted down and remolded or recycled. Nylon material also doesn’t heat up easily when used in high friction applications.

Nylon is usually combined with other materials to improve various qualities. For example, filling nylon with glass fibers increases its tensile strength while making it less flexible and more brittle.

With plastic injection molding, Retlaw casts glass-reinforced nylon plastic into the components you need for your industry.

Get Custom Nylon Plastic Parts

Properties of Nylon Plastic (PA):

| Name | Nylon (PA), or Nylon Polyamide |

| Chemical Formula | (C12H22N2O2)n |

| Melting Point (°C) | ~220°C |

| Tensile Strength | ~11,000 psi |

| Impact Strength | ~0.6 fit-lb/in notched Izod |

| Hardness Level (Rockwell) | R115 |

| Flexural Modulus | ~16,000 psi |

Common Applications for Nylon (PA) Plastic Include:

Nylon is an extremely versatile plastic material. Along with industrial and mechanical uses, Nylon is commonly used for a variety of products, including:

Fabric

Fiber Ropes

Food Packaging

Toothbrushes

Cookware

With plastic injection molding, nylon polyamide can be cast into gears, bushings, plastic bearings, and other components for mechanical equipment like engines.

Why Choose Retlaw for Nylon (PA) Injection Molding?

Choose Retlaw Industries for nylon (PA) plastic injection molding services and benefit from our comprehensive shop capabilities, transparent pricing, and commitment to total customer satisfaction. We have over 40 years of experience manufacturing custom components and assembling finished products with a long track record of success. Our dedicated and passionate team is what separates us from the competition, from the drawing up of part designs to the final assembly, you know it will be done right the first time with Retlaw Industries. Contact us today!

Plastic Injection Molding Services

Design & Engineering: Customized design and engineering for versatile nylon (PA) plastic applications.

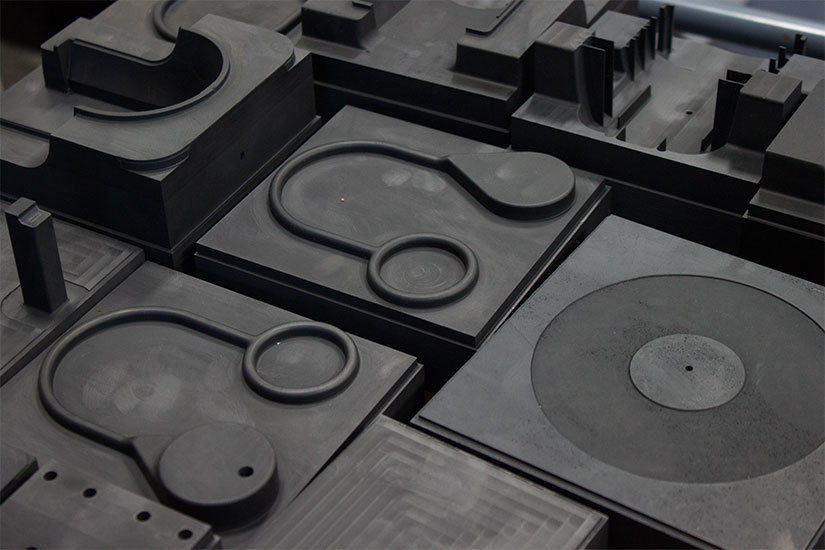

Tooling: Precise tooling for efficient nylon (PA) plastic molding.

Molding: High-quality molding for consistent nylon (PA) plastic products.

Assembly: Seamless assembly of complex nylon (PA) plastic components.

Prototyping: Rapid prototyping to refine nylon (PA) plastic designs quickly.

Challenges with Molding Nylon Plastic

As with any plastic material, there are some common issues that could potentially arise in the nylon thermoplastic molding process. Some of the problems that could occur include:

- Gassing – excess gas can cause defects in the nylon plastic, including a poor chalky appearance. Higher mold temperatures and poor ventilation can lead to gassing in nylon, but gassing can be deterred when you find the right temperature and allow gas to escape through proper venting during the molding process.

- Moisture - Poor drying can cause gassing and other potential scrap-producing defects in nylon. Nylon plastic is the most hygroscopic, meaning it easily takes in excess moisture when not properly drained. Always make sure the loader line and loader receptacle have been cleared of material to allow the barrel time to heat soak.

- Shrinkage – Nylon is a plastic material prone to shrinkage during the molding process. Nylon shrinkage can result in reduced strength, poor color, and warped edges, but properly controlling the heat and molding temperatures can help reduce shrinkage.

Custom Plastic Parts for Over 10 Industries

- Automation

- Fitness

- Lawn & Garden

- Electronics

- Construction

- Appliances

- Agriculture

- Food Production

- Warehouses

- Transportation

Nylon (Polyamide) Plastic Injection Molding Services Available Nationwide

Retlaw Industries ships plastic components nationwide including Colorado, Illinois, Indiana, Michigan, Minnesota, New York, Ohio, Pennsylvania, Washington, and Wisconsin!