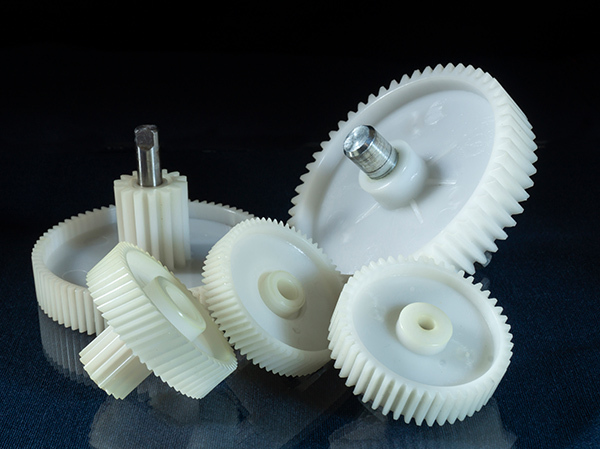

Parts Designed to Your Exact Specifications

Retlaw Industries is a trusted manufacturer of custom nylon plastic gears worldwide. We offer customers the best value in engineering and manufacturing nylon gears for their exact needs. Whether you need a few gears for a small project or a large volume for a high-demand application, Retlaw Industries has the capabilities and expertise to deliver the perfect solution. Contact us for a FREE quote to get your next project started.

What are Plastic Nylon Gears?

Plastic nylon gears are gears made from a type of plastic called nylon. Nylon is a synthetic polymer commonly used to manufacture small gears due to its strength, durability, and low friction properties. Nylon gears are often used in applications where high performance and low maintenance are required, such as in the automotive, aerospace, and medical industries.

Nylon gears can be made using various techniques, including injection molding (a specialty of Retlaw Industries), compression molding, and machining. They are typically used where metal gears are not suitable due to corrosion concerns, or where the gears need to be non-magnetic or non-conductive. Nylon gears are lightweight, making them a dependable option when weight is a concern. They also provide smooth operation while outputting less noise than their metal counterparts.

Types of Nylon Gears

- Nylon worm wheel gears: Nylon worm wheel gears are gears used in a worm drive system. A worm drive is a type of mechanical transmission consisting of a worm gear and a mating gear, called a worm wheel. The worm gear is a cylindrical gear with a screw-like helical thread, whereas the worm wheel is a flat gear meshed with the worm gear. In a nylon worm wheel gear system, the worm wheel is made from nylon, while the worm gear can be made from a variety of materials, such as metal or plastic.

- Nylon screw gears: Nylon screw gears are gears used in a screw drive system. A screw drive is a type of mechanical transmission consisting of a screw and a mating nut. The screw is a rod with a helical thread, whereas the nut is a cylinder with a matching internal thread. When the screw is rotated, the nut moves along the thread, converting rotational motion into linear motion. In a nylon screw gear system, both the screw and the nut are made from nylon.

- Nylon miter gears: Nylon miter gears are gears used in a miter drive system. A miter drive is a type of mechanical transmission consisting of two gears meshed at a right angle, or "miter," to each other. Miter gears are commonly used in applications where the transmission of power and torque between shafts at a right angle is required, as in printing presses, woodworking machinery, and other types of equipment. In a miter drive system, both gears are made from nylon.

- Nylon spur gears: Nylon spur gears are gears made from nylon having a simple cylindrical shape with teeth on the outside circumference. They are called "spur" gears since the teeth are parallel to the axis of the gear and transmit power and torque between shafts parallel to each other. Nylon spur gears are often used in applications where high performance and low maintenance are required and where the gears need to be non-magnetic or non-conductive and corrosion free.

- Nylon tooth bevel gears: Nylon tooth bevel gears have a conical shape with teeth on the outside circumference. They are called "bevel" gears since their teeth are perpendicular to the axis of the gear and are used to transmit power and torque between shafts at an angle to each other. Nylon tooth bevel gears carry all the benefits of nylon gears in strength, value, and resistance to corrosion.

- Nylon gear racks: Nylon gear racks are long, flat pieces of nylon with teeth on one edge used in conjunction with spur gears to convert rotational motion into linear motion. A gear rack meshes with a spur gear, and as the gear rotates, the rack moves along its length. Nylon gear racks offer dependable performance and value without the need for maintenance.

What are the Advantages of Injection Molded Nylon Gears?

- High-precision manufacturing: Injection molded nylon gears can be produced to the same precision as machined metal gears.

- Replicatable standards: Injection molded nylon gears can be replicated in bulk to exact standards easily.

- Lower costs: Injection molded nylon gears cost less than metal.

- Faster turnaround: Bulk orders of injection molded nylon gears have a fast turnaround process due to increased efficiency during production.

Nylon Gear Industry Use Cases

- Automotive: Nylon gears are used in automotive steering systems and other mechanical components. They offer high strength and durability while having low noise levels and smooth operation.

- Aerospace: Nylon gears are used in aerospace applications where saving weight and being resistant to corrosion are important. They are often used in aircraft landing gear systems and other mechanical components.

- Medical: Nylon gears are used in medical devices and equipment where corrosion resistance and low noise levels are preferred. You can find nylon gears in medical pumps, motors, and other mechanical components.

- Food processing: Nylon gears are used in food processing equipment due to their resistance to corrosion and easy cleanability. They are often used in conveyor systems, mixers, and other mechanical components.

- Packaging: Nylon gears are used in packaging machinery thanks to their high performance and low maintenance requirements. You’ll find nylon gears in conveyor systems, bottling and filling equipment, and other mechanical components.

- Printing: Nylon gears are used in printing presses and other printing equipment where high precision and low backlash are important. You can often find them in gear reducers and other components.

- Material handling: Nylon gears are used in material handling equipment including cranes, hoists, and conveyors due to their high strength and low maintenance. Nylon gears are often used in gear reducers and other mechanical components.

- Robotics: Nylon gears are used in robotics and automation systems thanks to their high precision and low backlash. They are often found in gear reducers and other mechanical components.

Retlaw Sizing Info

Retlaw Industries manufacturers several types of products. If you are interested in an adapter or idler pulley size that is not currently on our size chart, please contact us.

Why Choose Retlaw Industries to Manufacture Nylon Gears?

Retlaw Industries is headquartered in Wisconsin, supplying OEM and custom plastic products to clients worldwide. Using the powerful manufacturing process of injection molding, we have the experienced team and equipment needed to deliver exceptional finished products from start to finish. Trust our over 4 decades of experience to take your next project to the finish line.

Frequently Asked Questions on Nylon Gears

Is nylon good for gears?

Nylon is good for making gears in a variety of situations but it may not be the best choice in all. Nylon is a plastic material with good wear resistance and low friction, which can make it a good choice for gears subjected to high loads with the requirement of smoother operation.

One thing to consider is nylon is not as strong as some other materials, like steel, and it may not be suitable for use in gears that are subject to very high loads or need to be the most precise. Nylon can be prone to creeping, where it can deform over time under load and may not be as durable as other materials in certain environments. Overall, be sure to consider the specific requirements of the project when choosing a material for gears. Retlaw Industries can provide more information on the potential material solutions for your exact situation.

Are nylon gears strong?

Nylon gears are strong in situations where metal gears are not required. Nylon as a plastic material is not as strong as other materials like steel, making them not suitable for certain applications.

Nylon is a good choice for gears subjected to high loads or that need to operate smoothly due to its good wear resistance and low friction. You must consider the specific requirements of the project before deciding on a material to use for gears. Consult the team at Retlaw Industries for an opinion.

What is the best material to make gears out of?

The best material to use for making gears depends on the requirements of your particular project. In situations where higher sustained loads are common at high temperatures, metal gears are preferred. In low-friction environments where weight needs to be saved and the cost is of added focus, plastic gears such as nylon are a better choice.

Is nylon high quality?

Nylon is a type of synthetic polymer with a variety of manufacturing applications including clothing, ropes, and gears. Nylon has a number of attractive properties including good wear resistance, low friction, and high strength. However, the quality of nylon can vary depending on the specific composition of the material and the processing methods used to manufacture it.

Retlaw Industries only uses high-quality compositions of nylon to produce client products. Choosing to work with us means choosing an American company known for added quality control from beginning to end.

Custom Nylon Plastic Gear in the United States

Retlaw Industries proudly provides custom nylon plastic gear manufacturing services for all 50 states, including but not limited to: Wisconsin, New York, Pennsylvania, Washington, Indiana, Colorado, Michigan, Massachusetts, and Ohio!