Precision Plastic Injection and Quality Control

Composite USA Made Plastic Parts for OEM Markets

When a company needs thermoplastic OEM parts to build end products worthy of toppling their competition, they turn to Retlaw Industries. Knowing Retlaw will provide repeatable results gives B2C product suppliers the confidence put trustworthy products to market which they are proud to stamp their name on.

At Retlaw, we inject quality into every plastic product we ship out. Each product we make is tested along every stage of the process. From designers who virtually test each CAD/CAM plan, to tool makers who patiently machine molds down to the tightest tolerances; from thermoplastic injection specialists visually inspecting casts for surface flaws, to quality control specialists inspecting your product with micrometers, we live and breathe precision. For the experts at Retlaw, the destination of perfection is only attainable through precision at every step.

Get Precision Plastics at Retlaw

Retlaw Industries does not compromise on quality, because it's what our customers require -- Contact Retlaw today!

ISO 9001:2015 Certification; A.S.Q. Member

Our 44,000 square foot facility has achieved ISO 9001 certification, so you know your business can rely on Retlaw’s productivity and efficiency standards, and you know you’ll be treated to the best in customer service practices.

As an American Society for Quality member, we proudly adhere to the strict quality control standards the Milwaukee-based ASQ has been putting forth since World War 2. They are a global community built to support the champions of quality who are in turn helping the world’s corporations meet quality standards challenges of the future.

What’s more, Retlaw is proud to be affiliated with:

- TDMA – (Tool, Die, and Machining Association of Wisconsin): An association dedicated to the growth of the manufacturing industry in Wisconsin since 1937. They work with local legislators, schools, and companies to nurture cooperation for the future of Wisconsin manufacturing.

- AMBA – (American Mold Builders Association): Established in 1973 in Illinois, the AMBA unites mold builders across America and is dedicated to the welfare of the plastic mold-making industry.

Assurance in Quality Control at Retlaw

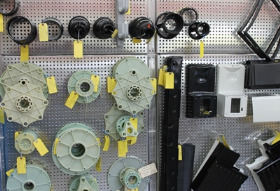

We employ a team of quality control specialists as a safeguard to test our products at the end of the production cycle. Quality controllers are housed in a separate room to give them total control over finished thermoplastic products, including our sprockets, idler wheels, adapters, and rebar chairs.

In order to achieve true accuracy in their inspections, our technicians take advantage of a range of available equipment and analysis, including but not limited to:

- 16” Quadracheck III Optical Comparator – able to display angular and linear dimensions, this comparator measures the geometry of a product against pre-determined limits. Comparators draw their benefits from the integrating of measurement with optics.

- Brown and Sharpe Microhite – a gauge used to accurately assess the precise height of an object

- Ohaus EP613 Digital Scale – a precision weighing tool to ensure consistency of plastic quality and thickness

- Meyer Gage Pins – highly accurate gauges for measuring bored hole diameters

- SPC Capability – (Statistical Process Control) A quality control method allowing Retlaw to use statistical analysis to decide how much conforming product one process is capable of creating. Takes machine component and tool, material, and worker degradation into consideration to maximize efficiency and reduce waste

If you demand quality and precision from your OEM parts, get in touch with the injection molding experts today.